Printed T-shirts are the new talk of the town for consumers, and clothing brands can’t stop thinking about it. When it’s about printing over clothing lines, you can choose from several printing methods. Different factors are essential in identifying the ideal printing method for your business.

If you are a clothing startup or searching for new ways to streamline your operation in more efficient and less effective ways, then picking up the right printing method for your clothing line is a crucial decision.

There are a couple of methods by which you can print the same design in your clothing line, but there will be a difference in the printing quality. Suppose your clothing product is a T-shirt. You can get any design printed over your T-shirt in a couple of ways. You can choose various t-shirt printing methods such as:

- Screen printing/silk screen printing

- DTG printing

- Embroidery printing

- Sublimation printing

- Vinyl cutting

- Heat transfer

We understand it gets tough to choose from a number of options, but certain practices make it easy for you to decide which printing methods are more suitable for you.

Criteria To Decide the Right Printing Method

The importance of choosing the right printing methods can be determined as, prime example, embroidered logos always look better over uniform rather than if they are printed. This is how a printing method plays an important role.

Here are some essential factors to consider with each printing method

-

Compatibility With Other Fabrics

Not all printing methods work well with all fabrics. Before you choose the printing method, you must also consider your material. For example, Dyeing sublimation is the proper method for you if you use thick cotton fabric.

-

The production times

Similarly, each printing method has its own production time. If you are looking for a 5000-quantity batch of T-shirts or hoodies, choosing a screening method won’t be good because screen printing methods take longer than other methods to print the design over the fabric.

-

The cost

Different printing methods come with different pricing because the procedure is other for every printing method. For example, the screen print methods use more different mesh screens for printing different colours over the fabric, increasing the cost.

On the other side, the DTG printing is less expensive.

-

The image or design quality

The image of the design you are willing to print over your clothing line is one of the critical things you must pay attention to. It’s essential to have a visually attractive and appealing design image to look good over your T-shirt. You must choose a reliable T-shirt printing method as per your design and the best fabric combination to make your design look the best.

If you want a high-quality print, one of the best printing methods for shirts is lithographic printing or screen printing, which allows the fabric to absorb the design with the best imprint. Many clothing suppliers use a screen-printing process to have an appealing strategy print over a clothing line.

-

The color accuracy

There are countless reasons to pay deep attention to what kind of color you will have in the finished product. The color and tone of your custom clothing line can even make or break your clothing line, as the human mind finds color easily readable and a broad audience like to wear clothes with unique and vibrant colors.

Also, you can explore some of the best apps for clothing design, such as Art Authority, business of Fashion or Pinterest, to explore new styles, designs and unique pattern ideas for your next clothing idea.

Your design may look dull, ineffective, and unattractive if it doesn’t have the power to be visually appealing and attract customers’ attention. That’s why color vibrancy and color accuracy are essential in making a clothing line successful. When creating custom denim jeans, you must ensure the colors and shades are perfect in your design.

-

The Turnaround time of manufacturers

It’s critically essential for your clothing brand to connect with a professional clothing manufacturer in manufacturing custom T-shirt lines for you. Working with a reliable manufacturer will ensure you deliver your clothing line to your doorstep quickly to reach the market quicker.

Also, you must focus and pick suitable printing methods according to your deadline. Digital printing is the best time-efficient, cost-effective method for fewer production units, making it an excellent option to rely on if you have a short deadline, unlike offset printing methods that require more time and effort. Offset printing methods need additional steps to set up, design, and print your clothing line.

-

Unique design requirements

You must note whether the custom design you are printing over the fabric is compatible with the printing method or not. You will need to consider the design type, color visibility, stitching options, materials, direct-to-garment printing, and flexibility of colors while choosing a printing method.

As with anything, there will be various things to measure and consider before starting an embroidery design project.

You create custom clothing lines for your clients or consumers by providing them with a high-class clothing line with their brand logo and design. You can do the production independently or work with 3rd party manufacturer for your designs. custom clothing manufacturers have been helping fashion brands and businesses by offering manufacturing services for their clothing lines.

If that’s your aim, then you must choose the right printing method for your clothing line.

There are all types of Custom printing options that you can choose from

To make things easy and more straightforward, we have written this blog that tells you about the 06 popular printing methods available in the market.

Screen printing

The t-shirt screen printing method is one of the best, most effective, and most widely used methods used among custom t-shirt manufacturers and clothing brands. The process involves using ink through a mesh stencil pressed onto the fabric to screen print the design into the material.

Screen printing is a cost-effective and efficient printing technique. It may be applied to various fabrics, including cotton, polyester, and mixes, and is perfect for patterns with one or two colors. Screen printing is economical for large orders and results in manufacturing brilliant, durable prints. It is not the best option for designs with many colors or detailed features and might be expensive for small quantities.

Benefits

- Best for clothing designs have one or two colors

- Results in vibrant colors and long-lasting prints

- Cost-effective for large manufacturing orders

When not to use

- Not recommended for designs with many colors or deep details

- Expensive for small orders

- DTG (Direct to Garment Printing)

DTG Printing

Direct-to-garment printing, or DTG, is a popular digital printing technique that is best for printing images directly over the fabric using a specialized inkjet printer. Designs with several colors are good to go with DTG printing, as images contain many colors and different shades, and the DTG printer can handle colors very well, making it one of the best t-shirt printing methods for printing clothing lines.

Little orders and keen detailing are perfect candidates. If you want, DTG produces a soft, comfortable, high-quality, and long-lasting print. Although the process is inappropriate for all fabric types, it works well on specific materials, including cotton blends, 100% cotton, Tri-blends, and bamboo. This printing method can be pricey for large orders.

With the flexibility of choosing from thousands of colors in DTG printing, you can create some of the best prints for shirts like Hawaiian t-shirts and many more that are trending in the fashion industry.

Benefits

- Ideal printing method for small orders

- Best for designs having many colors or deep details

- Produces soft, comfortable, and high-quality prints

When not to use

- Not suitable for all fabric types

- It might be expensive for large orders

- Dye Sublimation Printing:

Sublimation Printing

The dye sublimation printing process is another printing method that t-shirt manufacturers widely use. As the name says, the design is dyed over the fabric. The process includes heat, and designs are printed on a specific transfer paper and then transferred to fabric using the dye sublimation printing technique using heat.

The Dye sublimation process is used in many manufacturing as it supports many fabrics, including polyester and mixes, and produces long-lasting vivid, finely detailed prints. Nevertheless, cotton materials cannot be used with it, and small orders might be costly.

Benefits

- Accurate design, Vibrant colors, and detailed prints

- Suitable for a variety of fabrics, including polyester and blends

- Provide Long-lasting prints

When not to use

- Not suitable for cotton fabrics

- It can be expensive for small orders

Vinyl cutting:

Vinyl cutting is cutting designs from vinyl material and then applying the cut design over the fabric using heat. Heat makes the procedure more precise and permeant over the fabric. Vinyl cutting is one of the best methods for printing t-shirts for accurate composition and prints.

Vinyl cutting can create prints of exceptional quality and durability on various materials, including cotton and mixes. However, it is ineffective for designs with many colors or tiny details, so if your plan has minute details, you might have to consider another printing method.

Benefits

- Considerable for small orders

- Ideal for designs having few colors

- High-quality and long-lasting prints

When not to use

- Not suitable for designs having many colors or intricate details

- The method may not be perfect for all kinds of fabrics.

Heat Transfer:

The heat transfer printing method is widely used in the fashion industry. The process involves transferring the design over the fabric using special heat paper. The process is compatible with the print design over an array of fabric types, while the best materials for heat printing are polyester and cotton. However, transferring the plan over the vinyl fabric takes longer than cotton and other fabrics. Talking about the results, the heat transfers provide a high multi-color vibrant result.

Moreover, the heat printing process over the vinyl fabric and paper results in the best design looks. On the other side, the paper with heat transfer provides a flexible touch and smooth look over the clothing line with a simple design with text, shapes, or patterns. What makes heat transfer one of the best methods for printing t-shirts is its eco-friendly use of water-based mixtures.

Additionally, the heat transfer results in permanent design over the fabric as the design is transferred using high-temperature heat.

Benefits

- High-quality, color-full vibrant printing

- Cost-effective for small manufacturing orders

- Ability to produce an array of substrate

- Effective for small runs manufacturing

When not to use

- Offers a limited time of durability

- Don’t wash it often

- Less stretchability

Embroidery:

You might already have an idea about embroidery manufacturing. Although it’s one of the traditional methods of manufacturing clothes, still it’s in popular demand. The process includes a needle and thread, embroidery stitches, patterns, styles, or designs over the fabric.

Creating a high-quality, long-lasting print of exceptional quality and durability makes this method perfect for designs with fine details. Cotton and mixes are among the textiles that can be embroidered on. However, it might be pricey for huge designs or designs with numerous colors.

Benefits

- Best for designs with small details

- Results in high-quality and long-lasting print

- It is good to work with various fabrics, including cotton and blends.

When not to use

- It is not ideal for large designs or designs with many colors

- It may not be suitable for all fabrics.

What clothes printing should you choose for your clothing line brand?

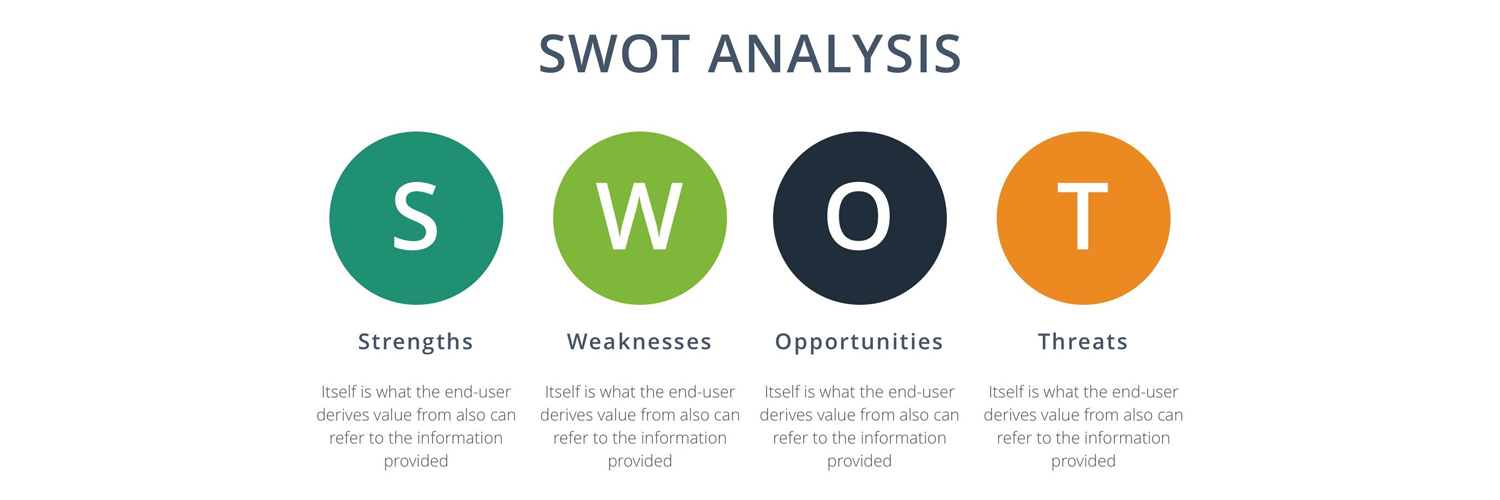

As mentioned above, there are various options for printing methods that brands are using to manufacture their clothing line. Well, some factors are involved in the decision to choose the best printing method for your clothing line. These factors include the quality of the printing method, design option, design durability, volume, cost, print area over your clothing line, and time. Therefore, all of these factors must be appropriately analyzed before you choose a printing method.

Before you choose a printing method, you need to analyze how many complex designs your clothing line needs. Then, following these methods, you will know whether you need DTG printing, screen printing, vinyl printing, sublimation printing, or any other type of printing.

At Zega Apparel, we aim to craft each piece of apparel to perfection using various manufacturing processes such as hand stitching, embroidery, screen printing and digital printing. Utilizing advanced production facilities with top-quality technology allows us to offer you premium products combining comfort and style – our apparel gives the best of both worlds.

Conclusion

There are various factors to remember when choosing a printing method for your clothing line, including style, feel, durability, and quality of clothes. Your designs may also be significantly altered depending on which printing method you choose when customizing T-shirts. Make sure you select the suitable printing method for your clothing line. In this blog post, we have mentioned the criteria to consider when choosing whether you’re making custom t-shirts for your company, event, or personal usage.

The best printing technique depends on your design, budget, quantity, and desired results. While specific printing techniques could be more economical for printing significant amounts, others might be more suited for producing detailed designs or vivid colors.